Rice Husk Pellets Making Test Using Flat Die Pellet Machine

Nowadays, more and more people realize the utilization of garden wastes and agricultural residuals such as rice husk, maize / corn stalk, wheat straw and so on. Pellet machine especially small sized flat die pellet machine is becoming more and more popular for farmers and individuals, which can easily turn the biomass rubbish into useful fuel pellets.

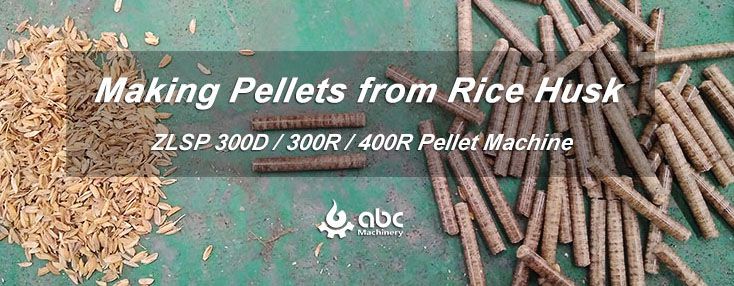

Recently we have made a test of rice husk pellets making by using our ZLSP series flat die pellet machine. The brief consequence of this pelletizing test is listed below. For detailed testing report, you are welcome to get in touch with us!

Test Reports of Making Pellets from Rice Husks

We tested two different moisture of rice husks feeding into the small pellet machine - 22% and 20%

300D (left), 300R (middle), 400R (right) Rice Husk Pellet Making Machine

| Test No. | Type of Pellet Machine |

|---|---|

| 01 |

ZLSP300 D type (22KW , 3 phase , 380V ,50HZ) |

| 02 |

ZLSP300 R type (22KW , 3 phase , 380V ,50HZ) |

| 03 |

ZLSP400R type (30KW , 3 phase , 380V ,50HZ) |

Raw Rice Husks for the Pelleting Test

Rice Husks after Crushing (left), Extruded Rice Husk Pellets (right)

Rice Husk Pellets Vs. Wood Pellets

The rice husk is used as a burning material due to its caloric value which is around 14 MK/kg that is equaling to 35% of the caloric value of diesel bunker oil which its caloric value is 40.5MJ/kg.It is utilized for power generation and the processes of gasification. When you compare with wood, rice husk is an effective burning material. Rice husk pellets are favored due to emission of low smoke and low amount of ashes.

Like wood, a rice husk is also a good material for biomass fuel pellets making production. Rice husk pellets have been gaining lots of interests all over the globe because it is a source of alternative energy over the common non-renewable fossil fuels.

Main Process of Rice Husk Pellets Making Production Line

For the ones who want to start a small process plant for rice husk pellets, you will need a complete set of :

- The screeners

or sievers remove the dust or other impurities in the rice husk thus protecting the processing machine in the pellet production line and also thus ensuring the quality of pellets is maintained.

- The grinder or hammer mills reduce the size of rice husk making it into fine power that will be ready for pellet production.

- Rice husk pellet making machine compresses the rice husk power in fuel pellets.

- The packing machine packages the rice husk pellets in bags with several specifications depending on the requirements.

- Finally,the final rice husk pellets are stored properly.

It is important to note that in the processing of rice husk pellets, the biomass blinders such as saw dust are the best. In the process of pelletizing, the lignin in the sawdust is melted under high temperatures in the pellet making machine. Melted lignin works as a binder that assists in the making of rice husk pellet.

For more information contact ABC machinery who are experienced in rice husk pelletizing technology. We supply complete rice husk pellet line. Besides, we have write about how to start a complete pellet manufacturing factory step by step, and tips for making pellets with high quality.

Economic Potential Of Manufacturing Rice Husk Pellets

Rice is one of the cereal grains that is a crucial staple food for a big population of the world especially in the East and South Asia the West Indies and Latin America. It is the second-highest worldwide production grain after corn.

The paddy rice husks have up to 20% of its weight and there are more than 100 million tons of rice husk produced worldwide. Approximately 70% of the latter is unutilized due to the problem of biodegradability of the paddy rice and disposal of combustion ash of the husks. The global demand for rice is estimated to be up to 780 million tons by 2020 and many tons of rice husks will be produced waiting for a better solution.

The use of the rice husk has been an economic source of the planter with the large scale of rice planting.Initially, the rice husks were seen as a waste product and discarded away, but with time it has been processed as byproducts with a lot of uses. It is a vital commodity. They can also be converted into rice pellets and used as animal beddings, as fuel bedding, production of cement and as fuel.